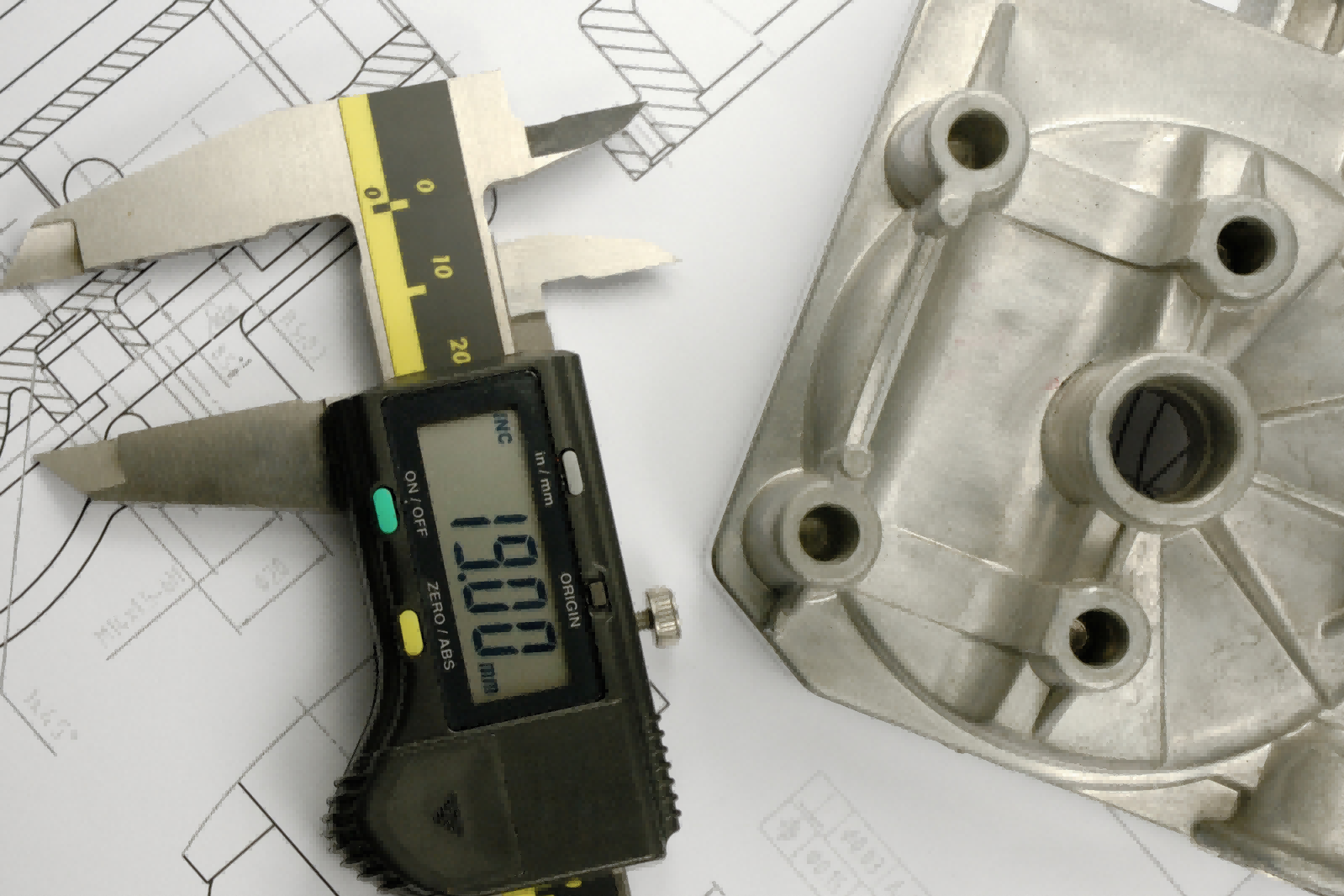

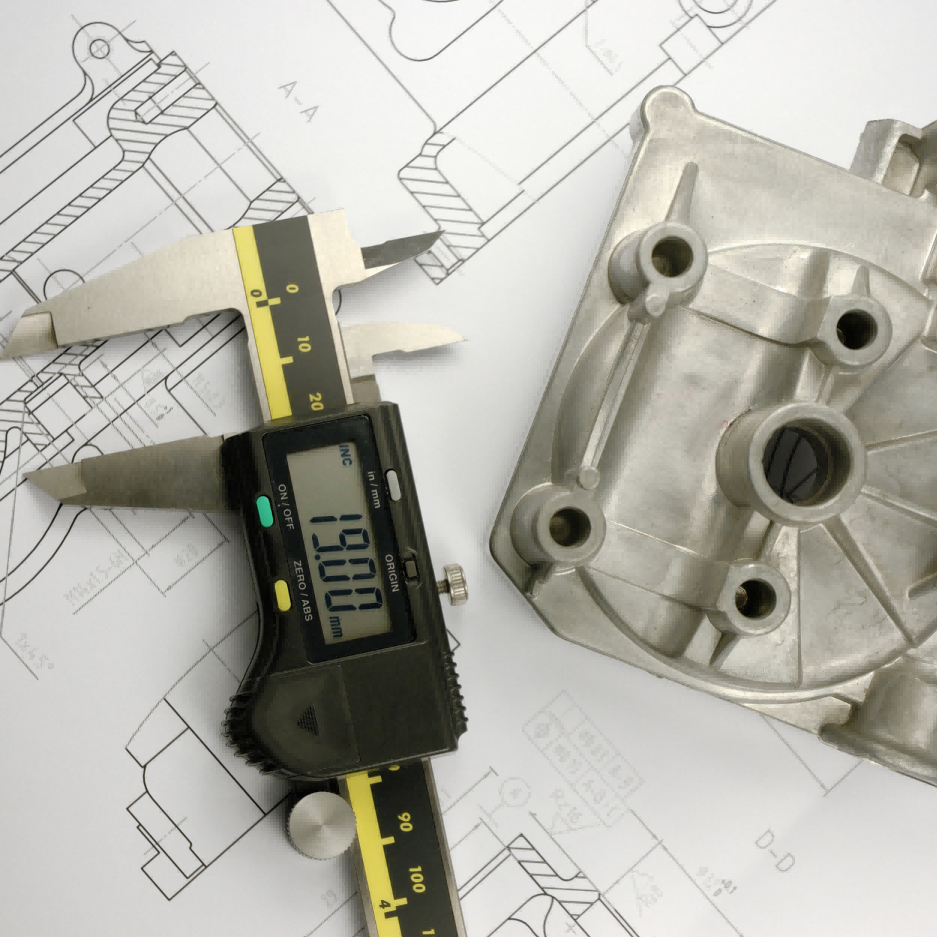

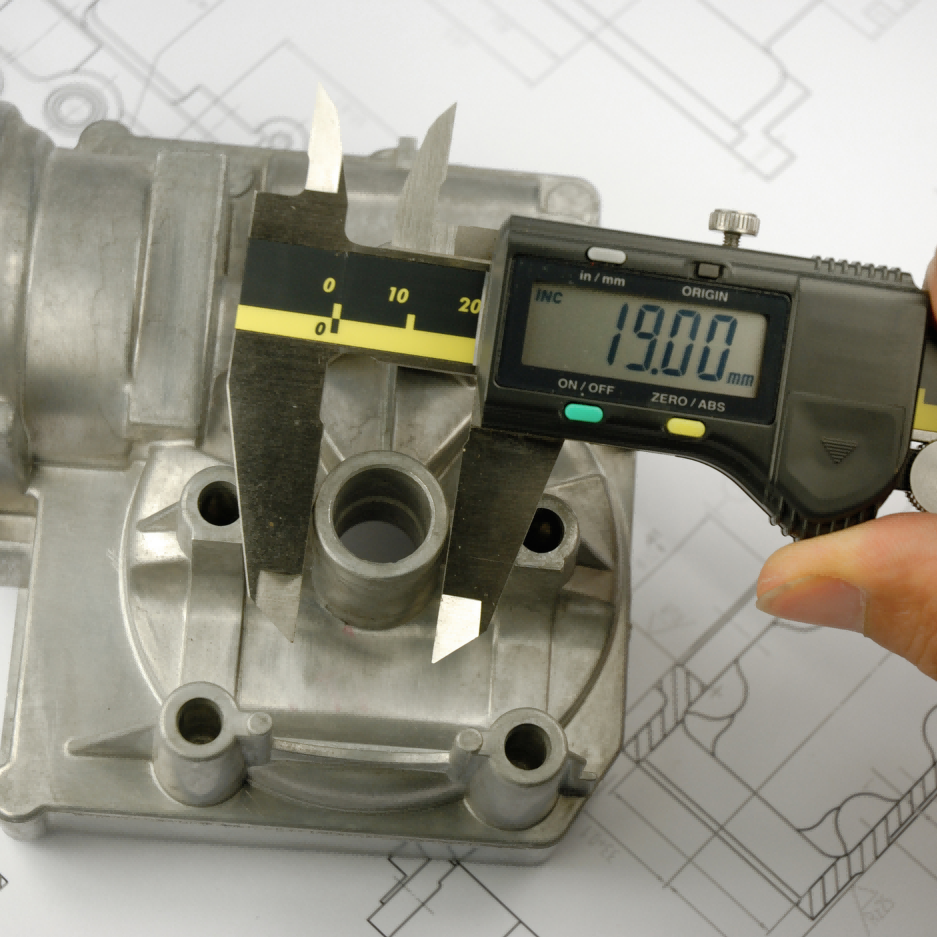

As a common measuring tool, calipers have a simple structure, easy operation, and multifunctionality. They can measure various sizes of objects such as length, width, height, depth, and inner and outer diameters. They are versatile and can meet different measurement needs

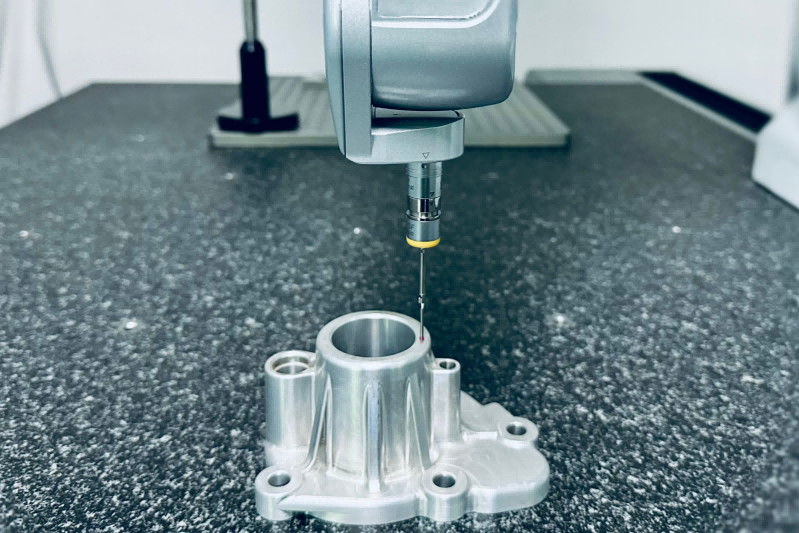

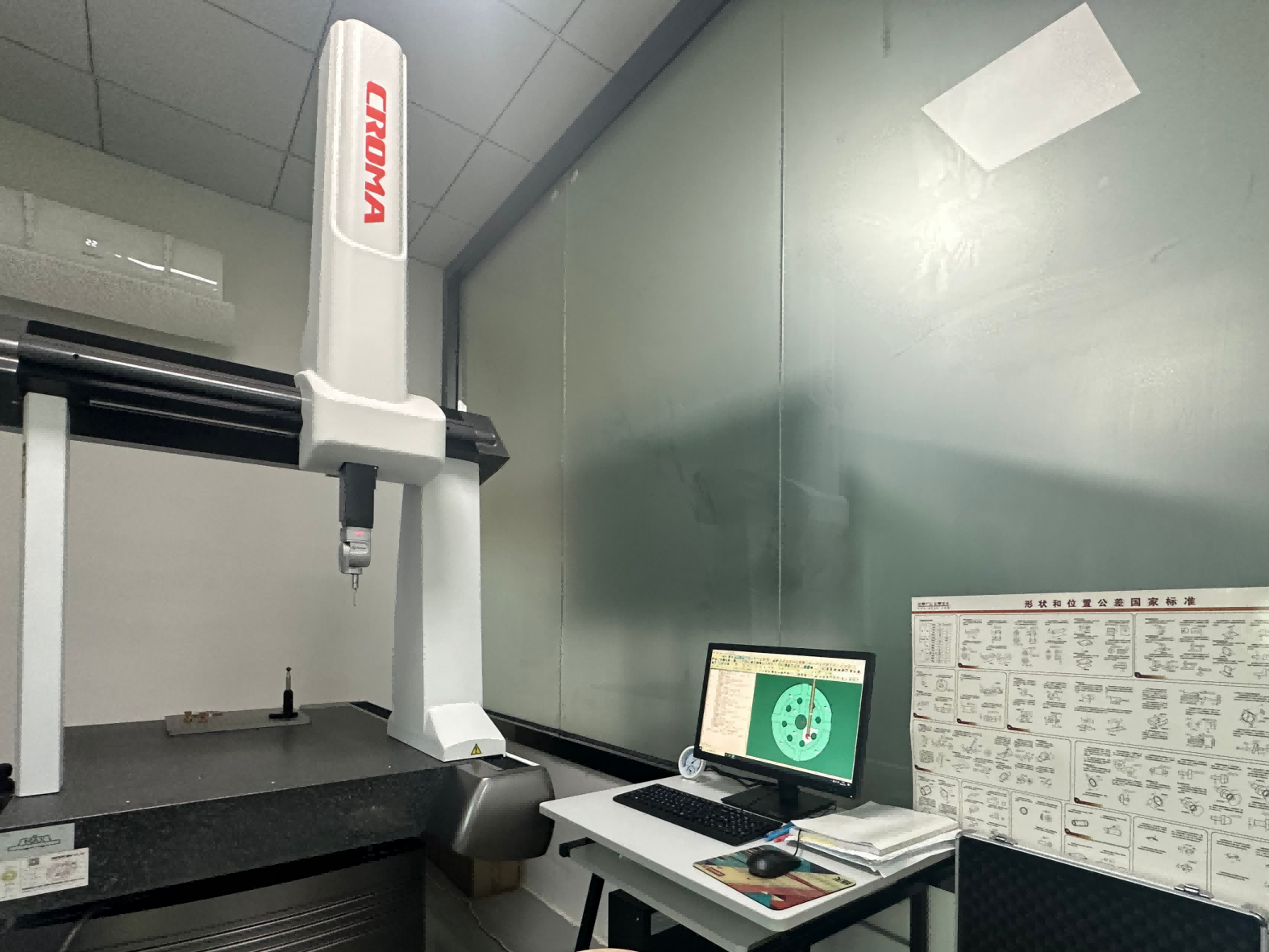

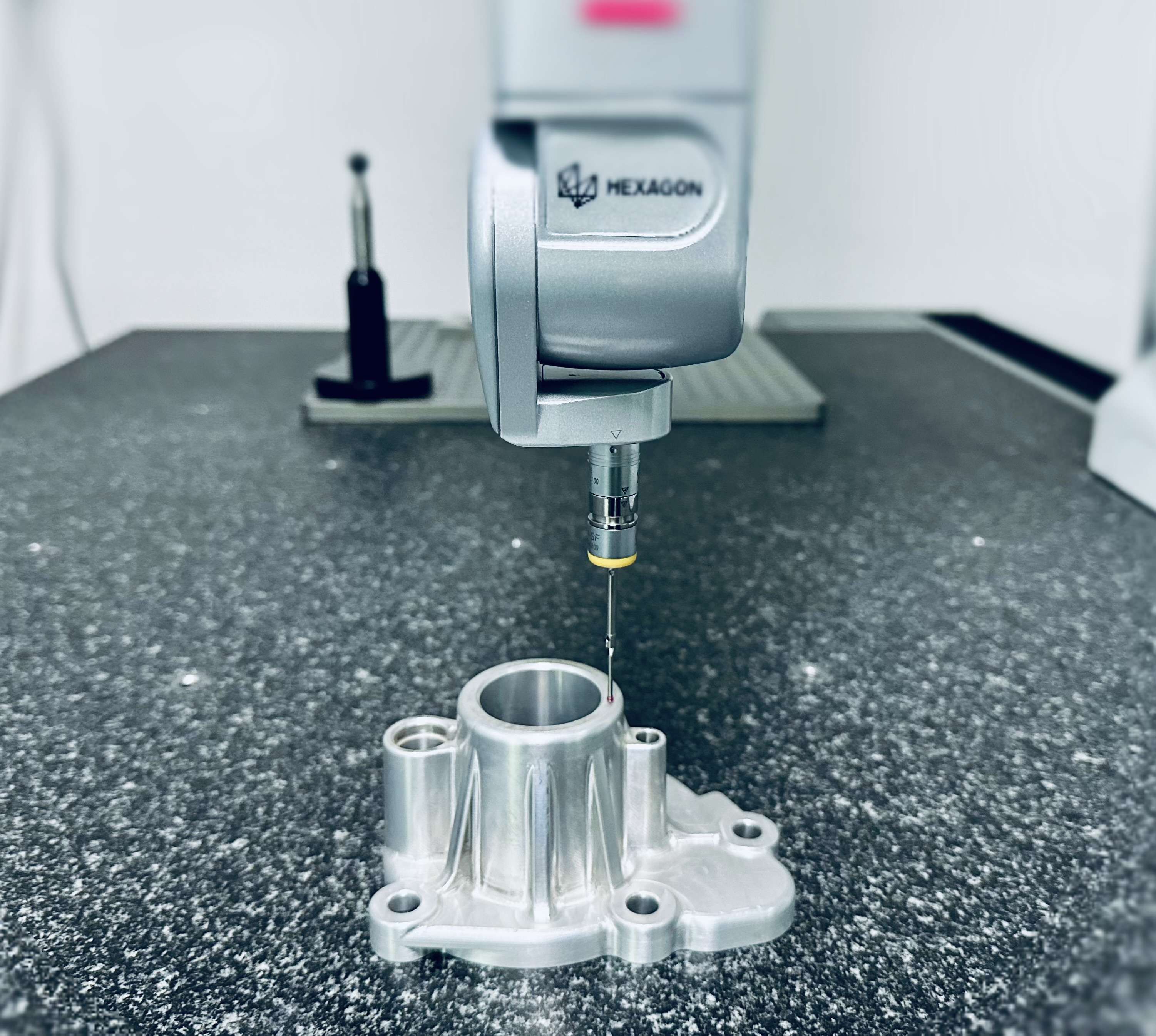

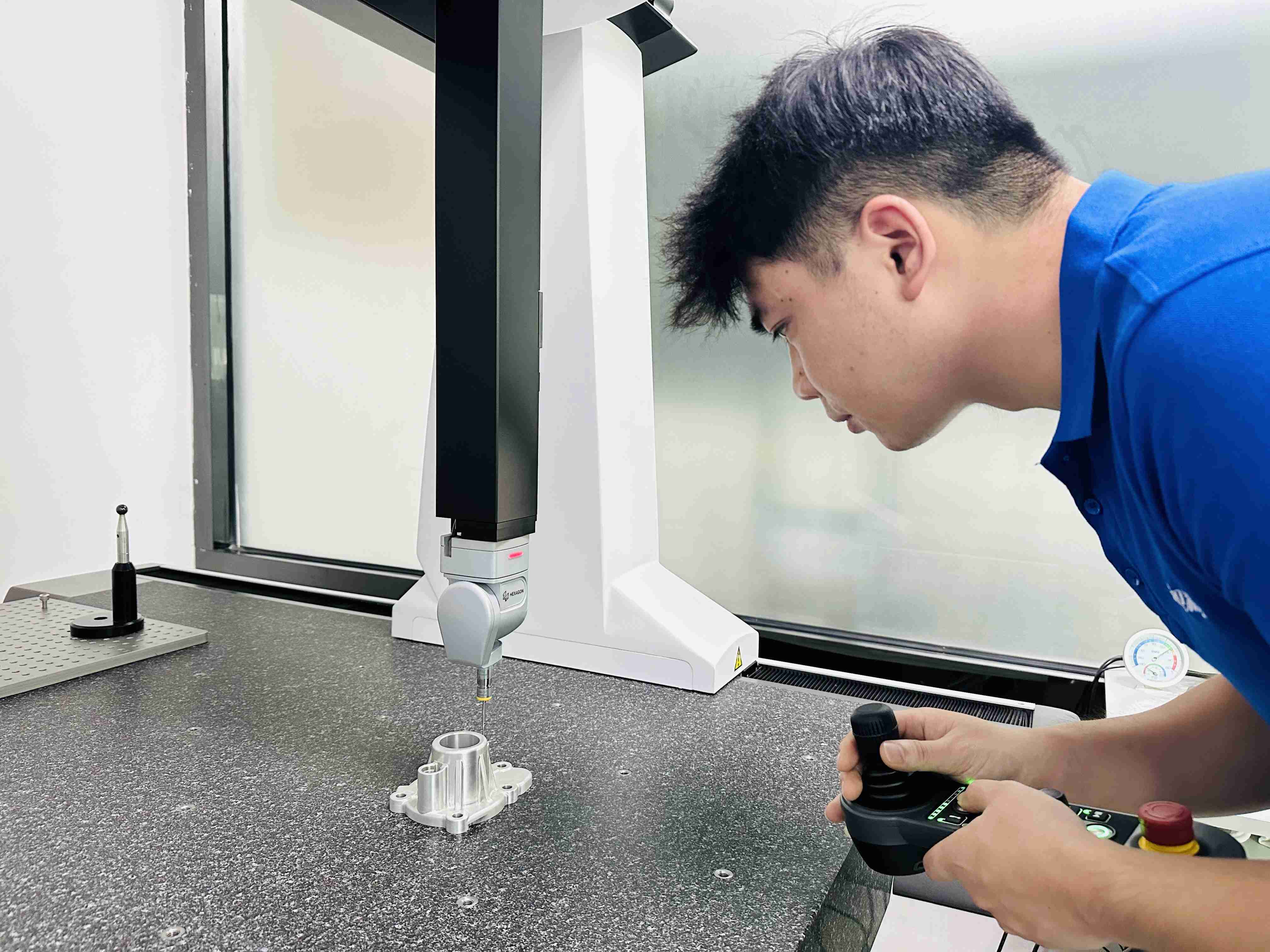

Three dimensional inspection is a technology that uses a coordinate measuring machine (CMM) to accurately measure the size, shape, and position of a workpiece. This measurement technique is based on the X, Y, and Z coordinate axes, which can comprehensively and accurately obtain the spatial geometric information of the workpiece. It can improve accuracy, efficiency, and optimize design more quickly, and is used in mold manufacturing, automotive manufacturing, aerospace, and other fields.

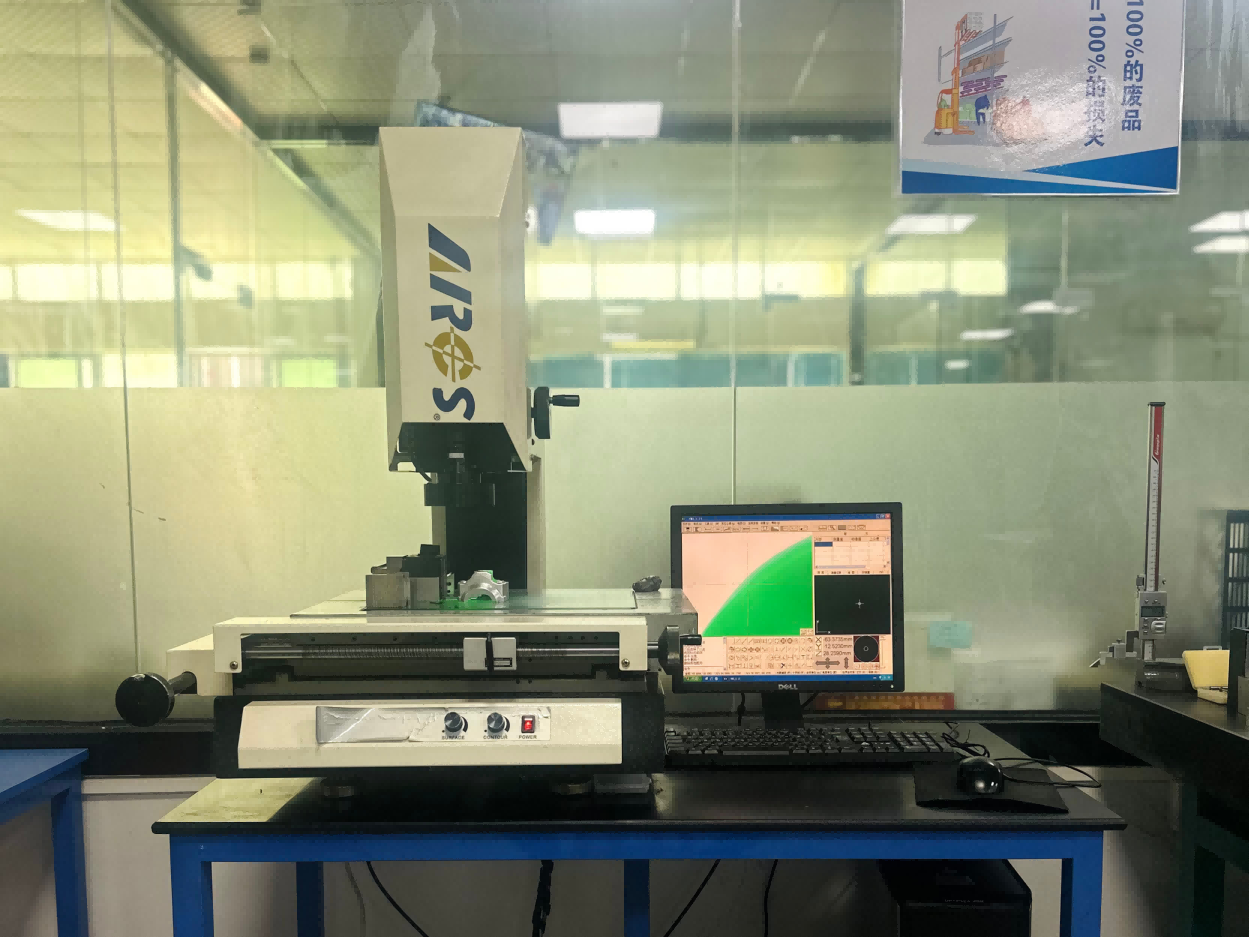

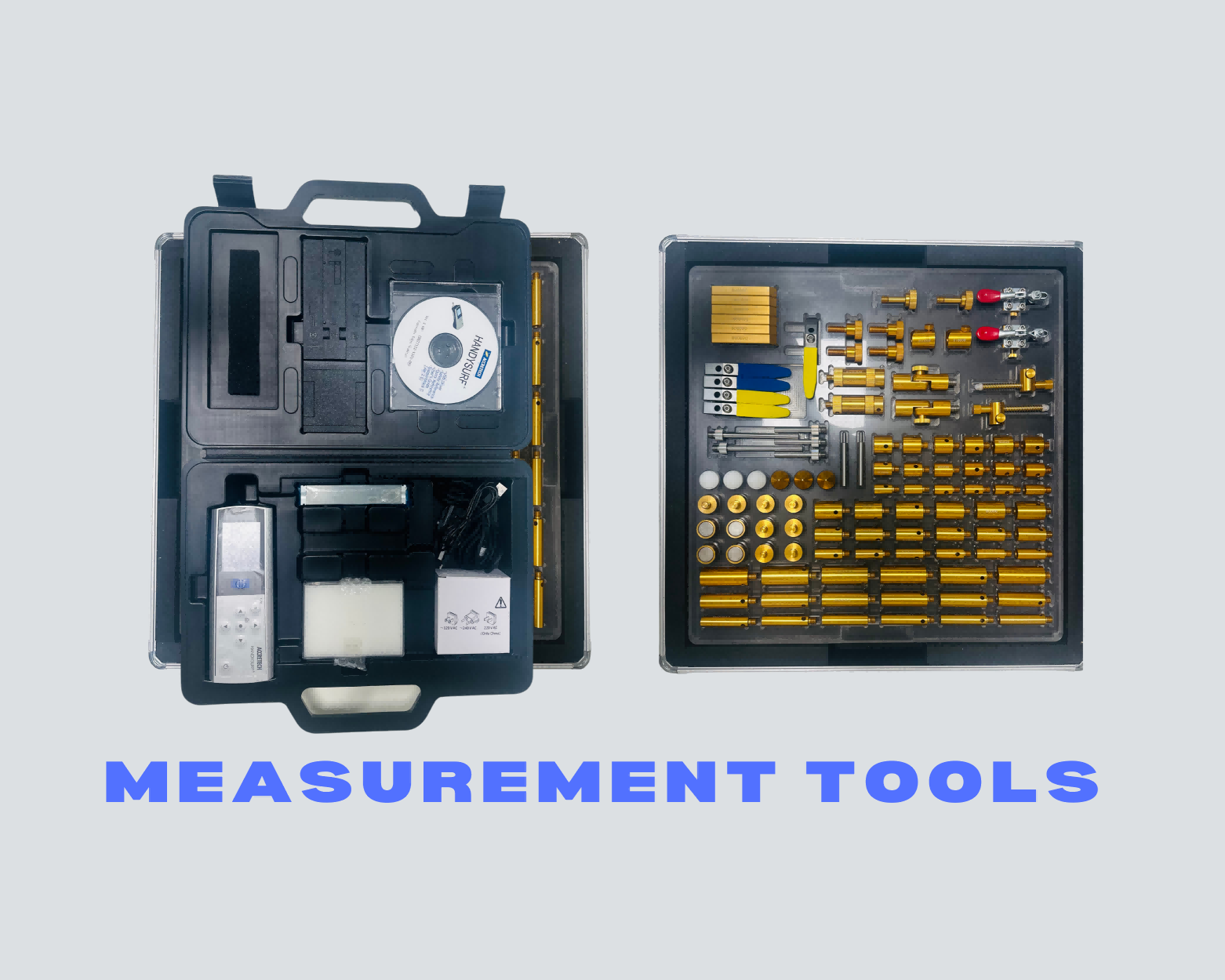

The projection profilometer measures the contour of an object through projection technology, without the need to touch the object being measured, avoiding the damage to the surface of the object caused by traditional contact measurement. High precision measurement, rapid detection, wide applicability, and easy operation ensure the consistency and stability of product quality.

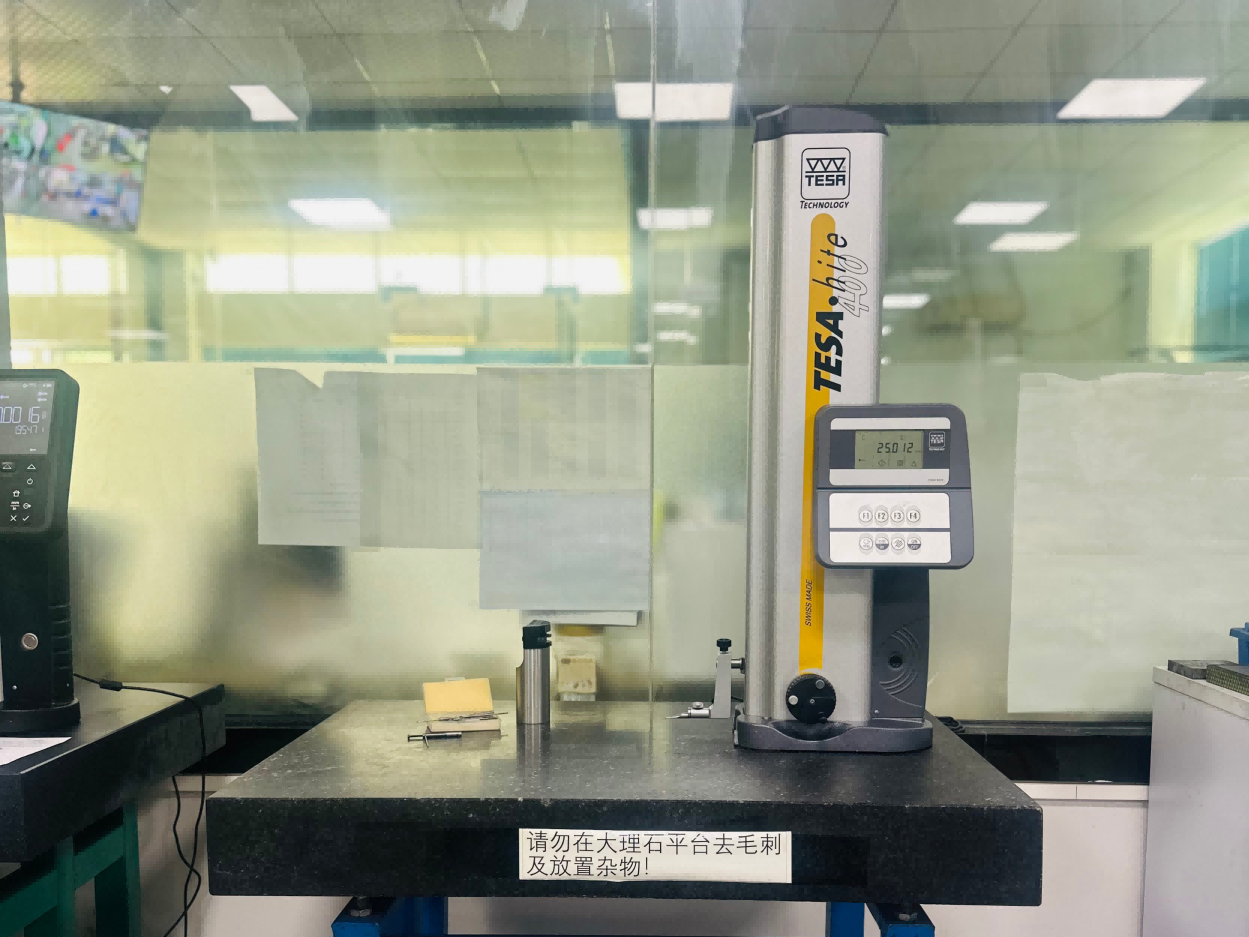

The pursuit of accuracy has always been one of the core pursuits. As a common measuring tool, the height measuring instrument has become an indispensable helper in industrial production due to its high accuracy and reliability. In addition to accurately measuring the height of the workpiece, the height measuring instrument can also measure shape and positional tolerance dimensions, such as perpendicularity and straightness. On some models of measuring instruments, we can even measure depth, groove width, inner and outer aperture, etc.