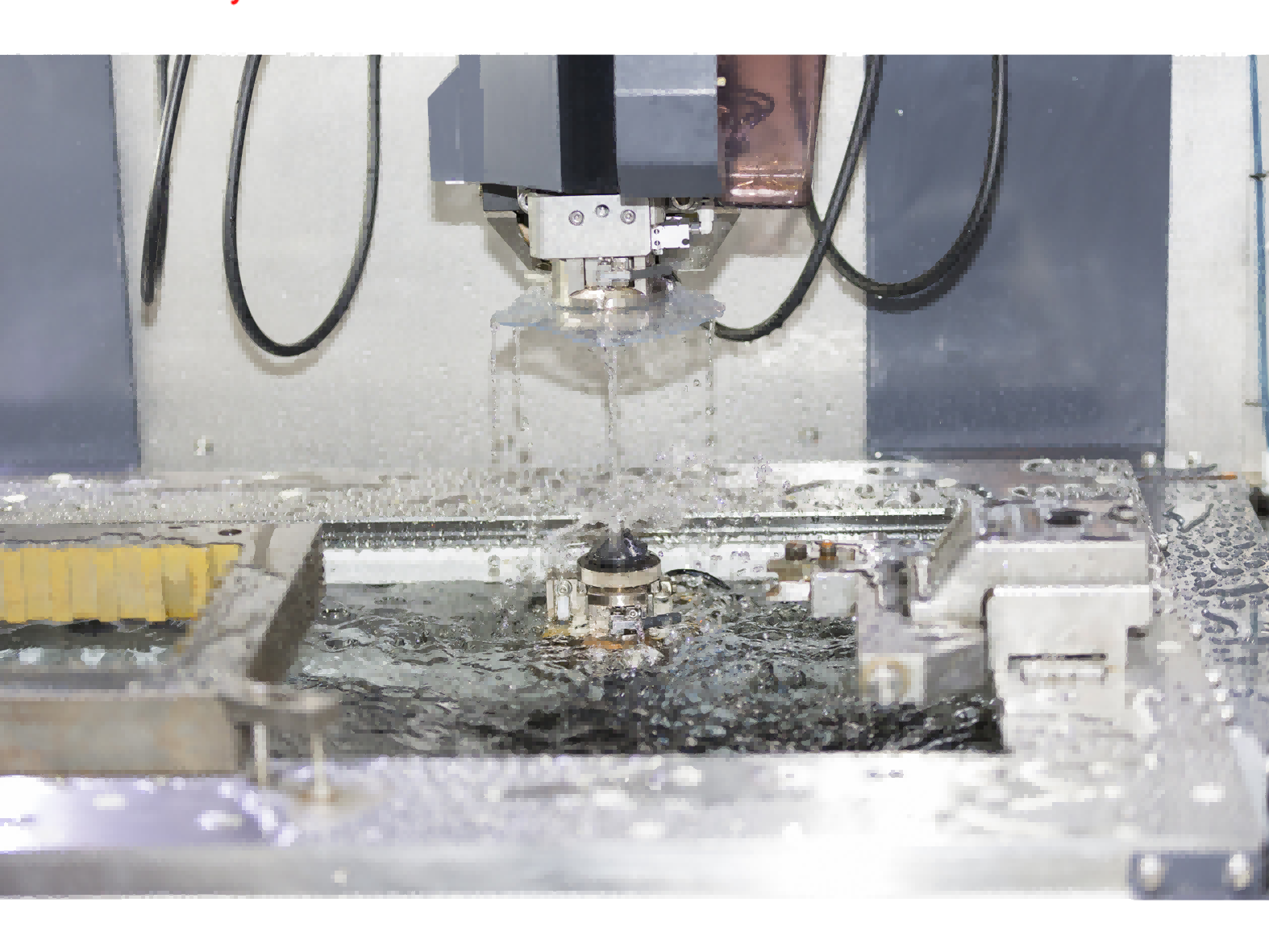

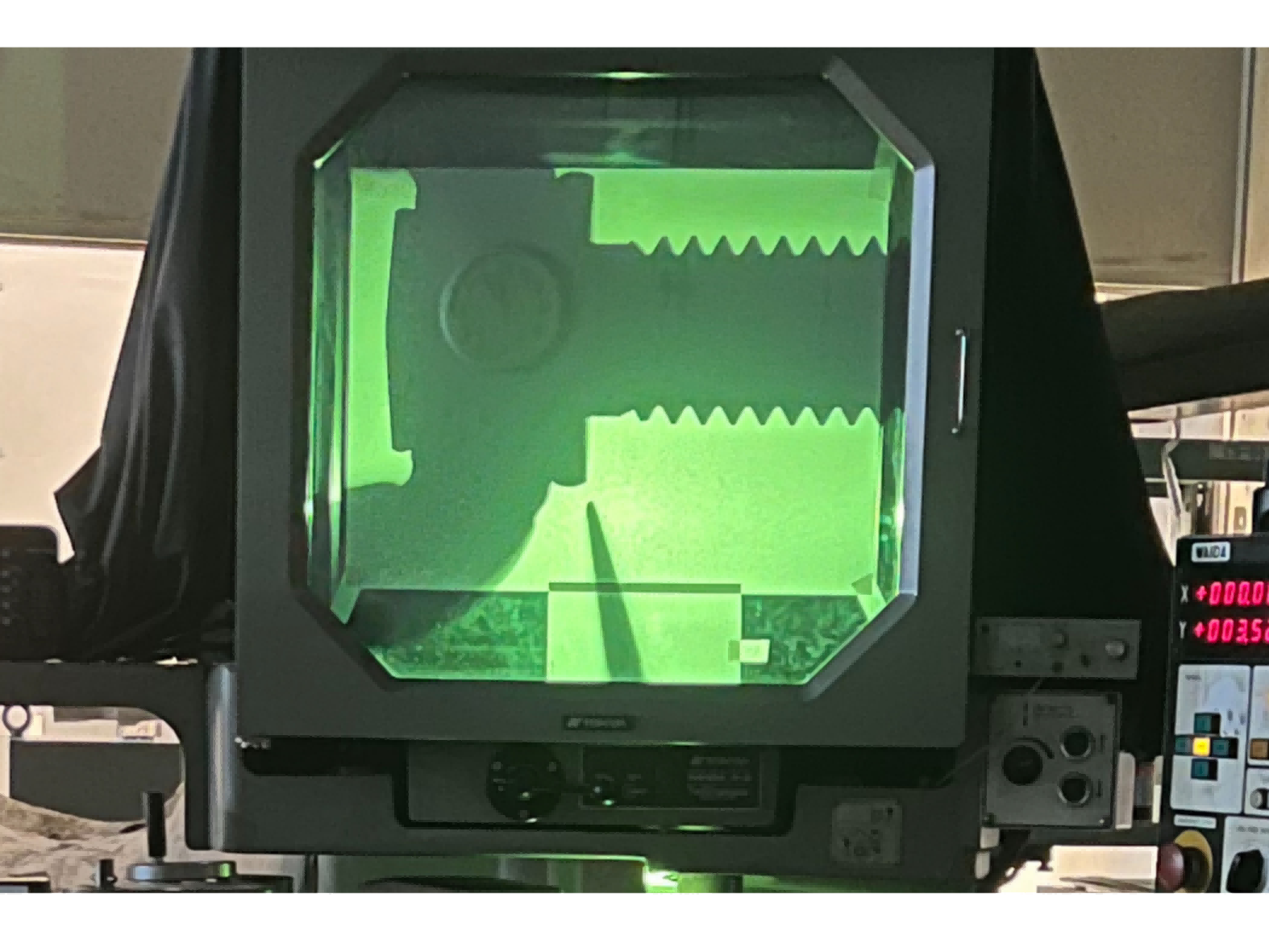

Wire cutting is achieved through multiple cutting techniques to achieve extremely high dimensional accuracy and surface quality. Widely used in precision mold manufacturing, medical devices and other fields,

Processing materials are not only suitable for ordinary steel, but also for difficult to process materials such as hard alloys, stainless steel, titanium alloys, etc.

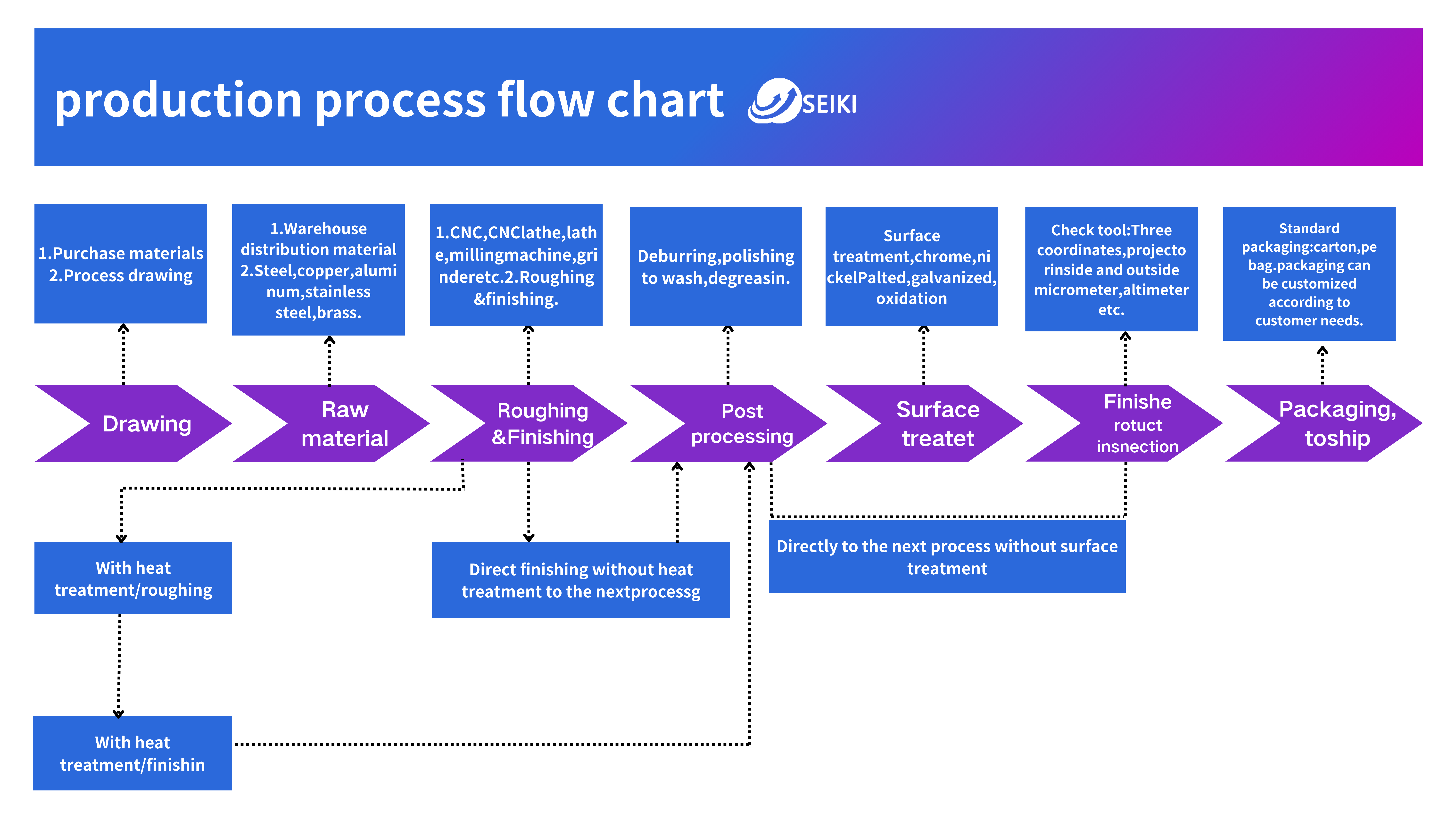

The company has precision machining equipment and testing instruments, including five axis, four axis, and three-axis CNC machining centers, CNC lathes, wire cutting machines, grinders and Profile polishing, projectors, etc.

Maintain consistency in large-scale

production through detailed records

Our commitment to consistency and

quality control is unwavering.

MANUFACTURE

MANUFACTURE

We always strive to provide customers with efficient and high-quality service for the purpose; to fast and efficient communication, reasonable cost, comprehensive and flexible service for the concept; to provide customers with a very competitive price for the purpose.

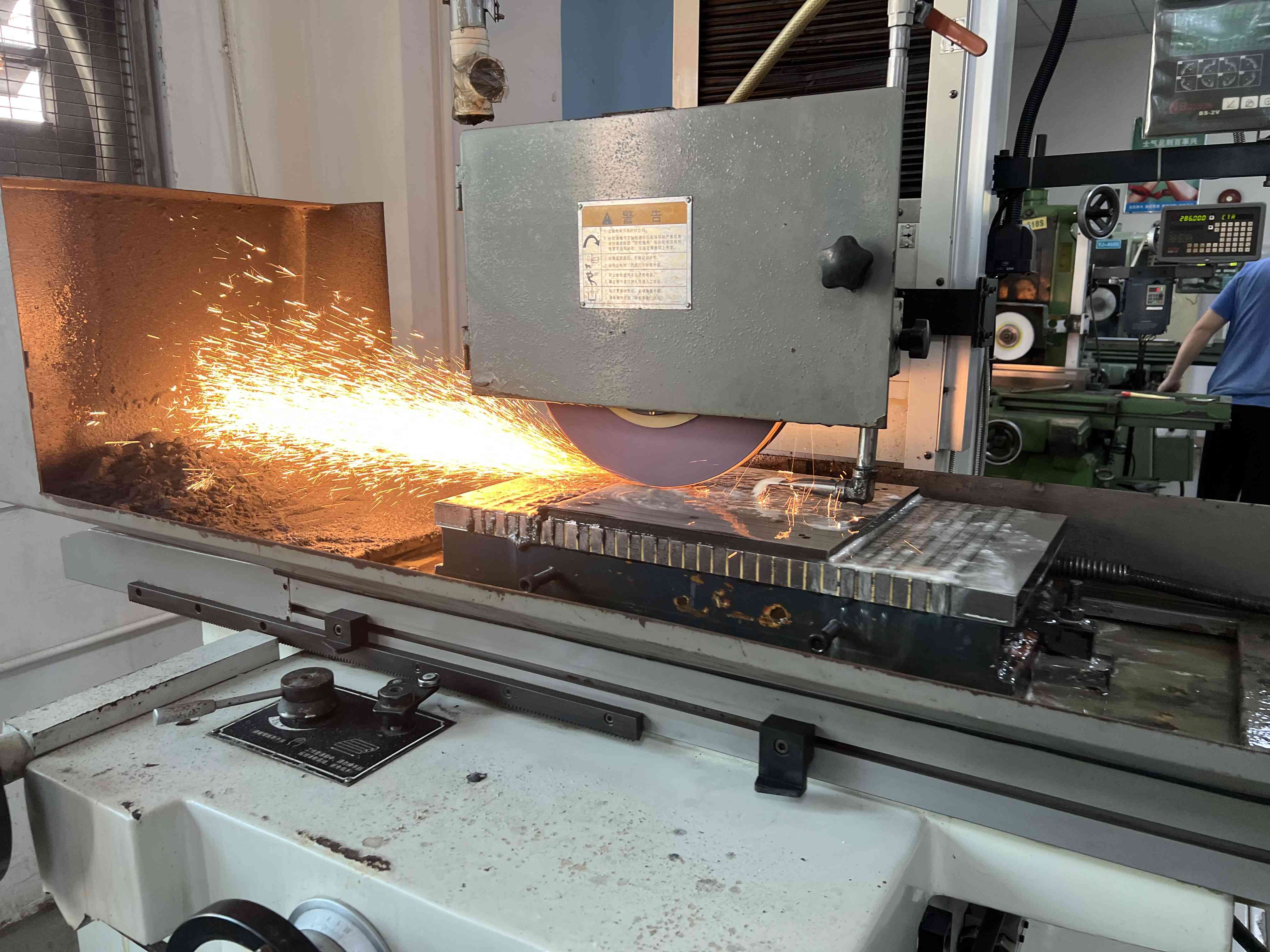

Profile polishing is a precision machining method that achieves the required precision and surface quality by finely grinding materials.

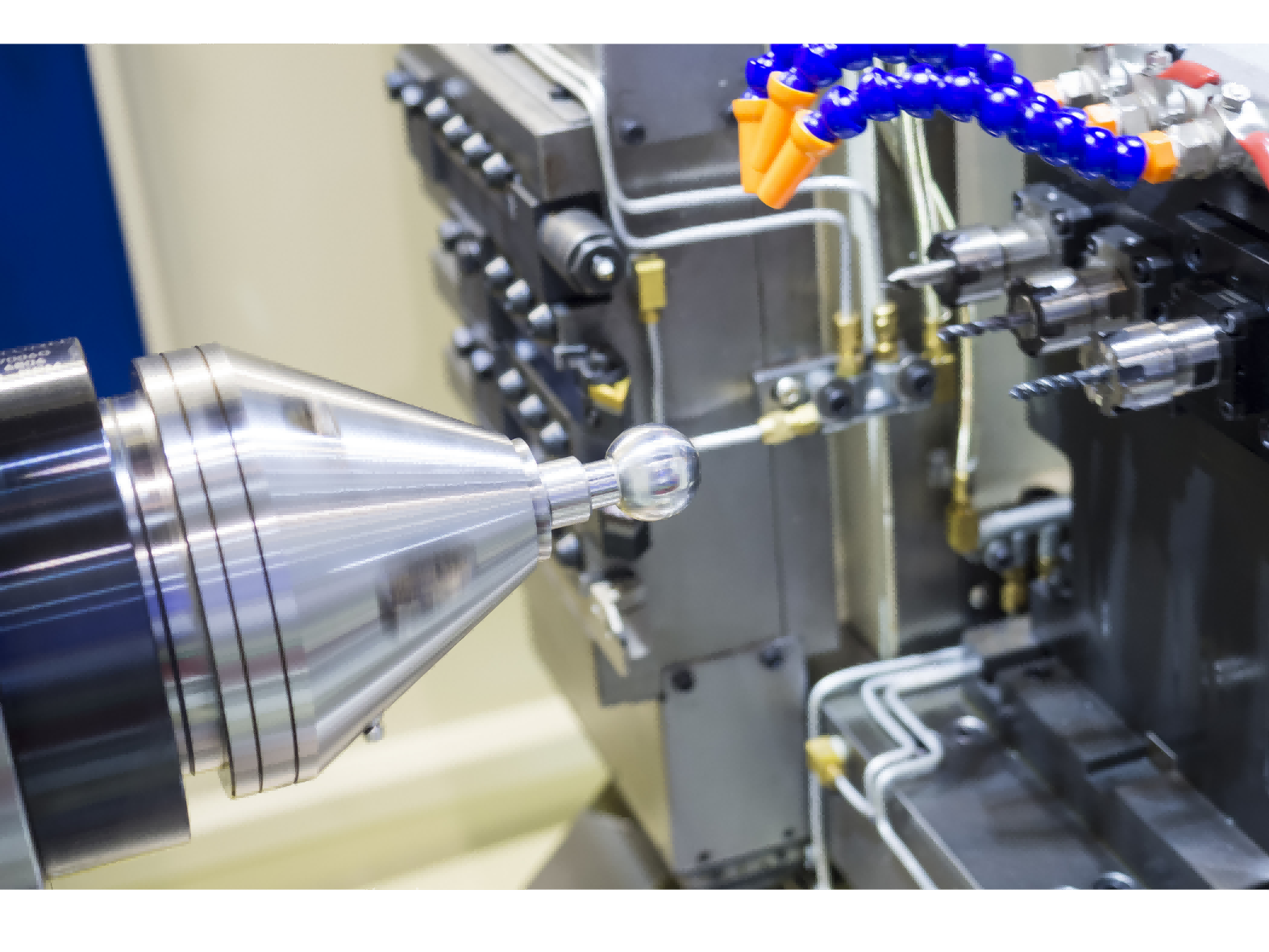

As an advanced machining method that integrates turning and milling functions, the combination of turning and milling enables the workpiece to complete all machining steps on the same machine tool, greatly improving production efficiency. Widely used in industries such as automobiles, aviation, aerospace, and precision molds.

CNC machining centers achieve efficient and high-precision machining of complex components, improving efficiency and quality, shortening manufacturing cycles, and reducing production costs in aerospace, automotive manufacturing, and medical device processing.

MANUFACTURE

In addition to our expertise in numerical control technology, we also have rich experience in mold and die-casting processes. Our comprehensive capabilities enable us to provide one-stop services from prototype development to mass production, offering customized solutions across different industries.

Message Feedback

We always strive to provide customers with efficient and high-quality service for the purpose; to fast and efficient communication, reasonable cost, comprehensive and flexible service for the concept; to provide customers with a very competitive price for the purpose.

MANUFACTURE