Message Feedback

We always strive to provide customers with efficient and high-quality service for the purpose; to fast and efficient communication, reasonable cost, comprehensive and flexible service for the concept; to provide customers with a very competitive price for the purpose.

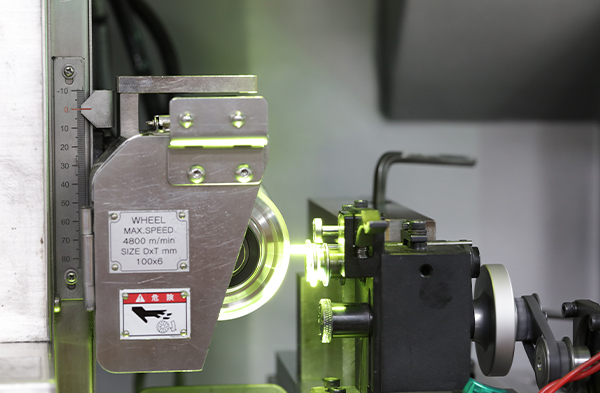

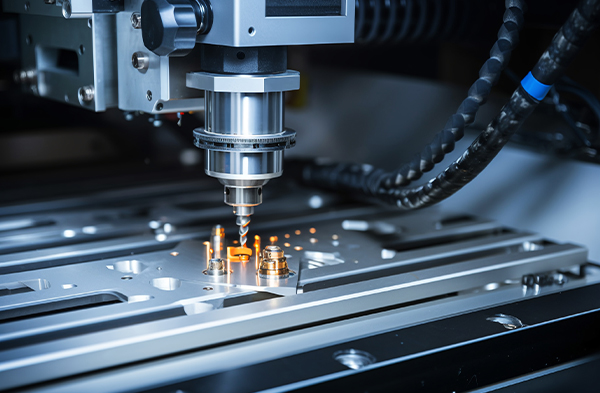

CNC Machining

CNC machining can be used to create a wide variety of parts and components, from simple objects like bolts and screws to complex items like engine parts and aerospace components. It offers a high degree of accuracy and precision, as well as the ability to produce large quantities of parts quickly and efficiently.

Accuracy: 0.002

Accuracy is our hallmark, reflected in our ability to achieve outstanding precision of up to 0.002. This unparalleled precision ensures that every component we manufacture meets strict quality standards. From complex medical equipment parts to professional automotive parts, our commitment to precision ensures first-class, carefully manufactured parts to meet the most demanding requirements.

Other Processes

In order to develop into a comprehensive custom parts manufacturer, we have established a strong supply chain and expanded our cooperation to cover a range of interrelated process services, including profile extrusion, injection molding, precision casting, and more. In addition, we also offer trading company services,And there are cooperative factories in Japan.

Finishes

At SEIKI Precision, we offer more than just excellent CNC machining - we take your products to the next level through comprehensive surface treatment services. Our capabilities are not limited to precision manufacturing, but also ensure that your components meet the highest standards of durability, aesthetics, and functionality.

Die Casting Processing

Die casting can produce parts with strict tolerances and minimal machining. Its economic benefits and high durability reduce material waste and improve productivity. Used for aerospace shells and brackets, cylinder heads, gearbox housings, cylinder blocks in the automotive industry, manufacturing electronic components, connectors, radiators, and shells.

Comprehensive manufacturing capability to meet different needs

In addition to our expertise in numerical control technology, we also have rich experience in mold and die-casting processes. Our comprehensive capabilities enable us to provide one-stop services from prototype development to mass production, offering customized solutions across different industries.

Maintain consistency in large-scale production through detailed records

Our commitment to consistency and quality control is unwavering. Every order is carefully archived and the production process is recorded in detail. This meticulous approach enables us to maintain consistency in the manufacturing process and seamlessly meet different production volumes from small batches to large-scale production.

Mold Processing

Mold making refers to the processing of forming and blanking tools, as well as cutting and die-cutting molds. From electronic connectors to automotive instrument panels, workpieces can be molded using molds.

Manufacturing flexibility

Our engineering team excels in efficiently handling complex designs, ensuring cost-effective solutions without compromising quality. Through collaborative discussions and innovative problem-solving, we deliver complex parts with a competitive advantage, providing unique and complex structures tailored to customer needs.